Read NOAHs press release on the project Resalt

First important step

This is a first important step towards reusing materials from fly ash.

"The recycling of salt has a double effect. We get to reuse the salts from the fly ash. In addition, removing salts provides opportunities for further resource utilization", says Terje Ulltang, project owner for NOAH's major investment Resalt.

Resalt - kicking off in April

In January, construction of the salt recovery pilot will begin.

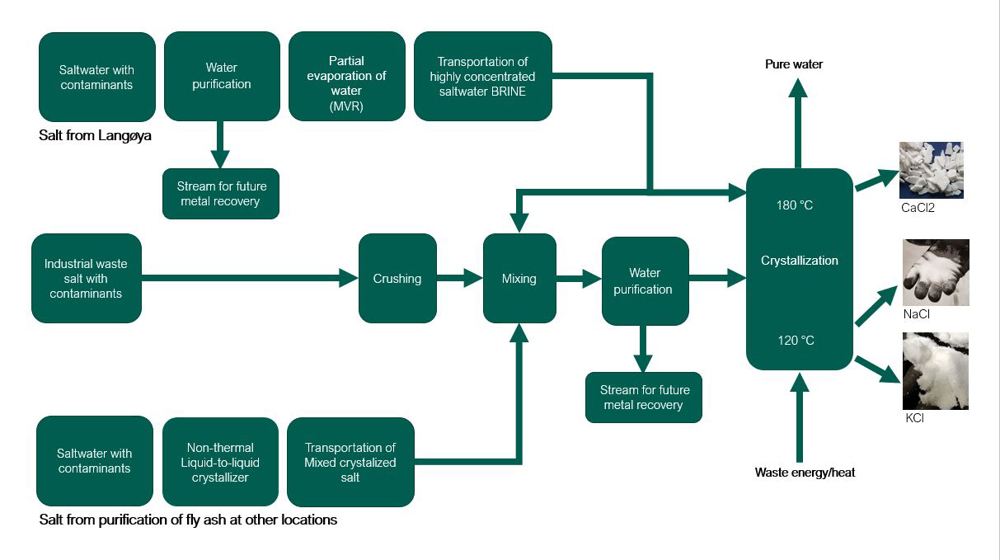

"Resalt becomes a crystallization plant, for crystallization and separation of different salts", Ulltang explains. NOAH recently signed a lease agreement with HIP Eiendom AS, for the construction of the pilot.

Project manager Simen Bergan, together with three or four NOAH colleagues, establish themselves in office and meeting room rigs located outside the pilot hall. Together with Swiss partner SEP Salt & Evaporation Plants Ltd., Bilfinger and other resources, NOAH is carrying out construction and plans to start up the plant from Easter.

Industrial cooperation

After NOAH have treated the fly ash at Langøya, they plan to extract various salts, including sodium chloride, potassium chloride and calcium chloride. The salts will be cleaned and sold commercially to Norwegian industrial customers.

"By establishing Resalt in an industrial cluster, it is possible for good industrial cooperation both in terms of commercial sales of the salt, and in terms of being able to utilize any surplus energy from other production," says Ulltang.

Enthusiasm for even greater environmental effects

"Working with Resalt we have experienced a great enthusiasm that we can make this bigger than just the salts from Langøya. We are now conducting market research. Together with Bergfald Miljørådgivere, we are looking for more waste streams that contain recyclable salts in industry at home and abroad, and are starting to find a number of opportunities, especially in Scandinavia", says Ulltang.

Potentially a profitable business idea

Resalt is dependent on large volumes to achieve the necessary profitability in the project, Ulltang points out.

"We want to get Resalt to stand on its own two feet, and now we see that this is starting to become a good business concept. Of course there is competition, and there are others who do recycling, but maybe we have a specialty and a supplement to what others can offer. The industry needs more salt and we see that the demand is greater than supply."

"If we get more good partners in the project, this could be a very good circular project", emphasizes the project owner, Terje Ulltang.

Good strategy

"This is a good moove in the circular economy, and we are cheering on, says Sverre Gotaas, director of Herøya Industripark AS.

"It is great that NOAH and others are focusing on circular economy. In circular economy, it is natural and sensible to establish oneself close to customers and users. This industrial region uses a lot of salts, and both at Herøya, in Bamble and in the region in general, there is a good supply of customers. In addition, there is also access to resources, and easy to get to and from."

About NOAH and Resalt

NOAH has a permit to annually receive 500,000 tonnes of fly ash, residual acid and other inorganic residual fractions. The acidic and alkaline fractions give a neutralized and chemically stabilized gypsum that is used to recreate the original landscape at Langøya. The plaster contains salts, which through the planned technology development will now be recycled.

NOAH has received up to NOK 10 million for the establishment of the pilot plant. In addition, the company contributes a minimum of NOK 17 million. The results from the pilot will be decisive when the company is to assess the major goal - a full-scale recycling plant for salts with an investment framework of NOK 300 - 500 million.

26. November 2020