The glass workshop is located within the Herøya Forskningspark (Research Park) as part of Bilfinger’s plastics workshop.

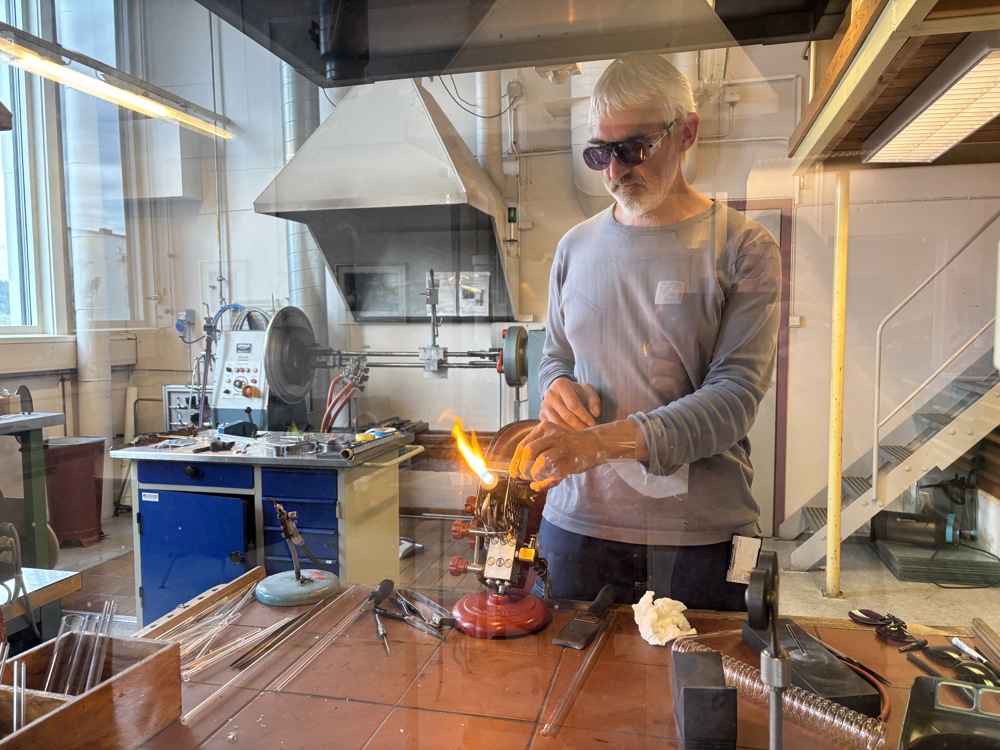

“I completed a three-year degree in scientific glassblowing at the University of Kassel. After graduating, I worked as a technical glassblower at the University of Ulm. For eleven years, I was master glassblower and head of the workshop there,” explains Konstantin Kraft-Poggensee.

For more than ten years, he has been the professional lead at the workshop at Herøya.

Combining glass with other materials

The community of scientific glassblowers in Norway is small – Konstantin Kraft-Poggensee is one of only about ten practising the craft in the country.

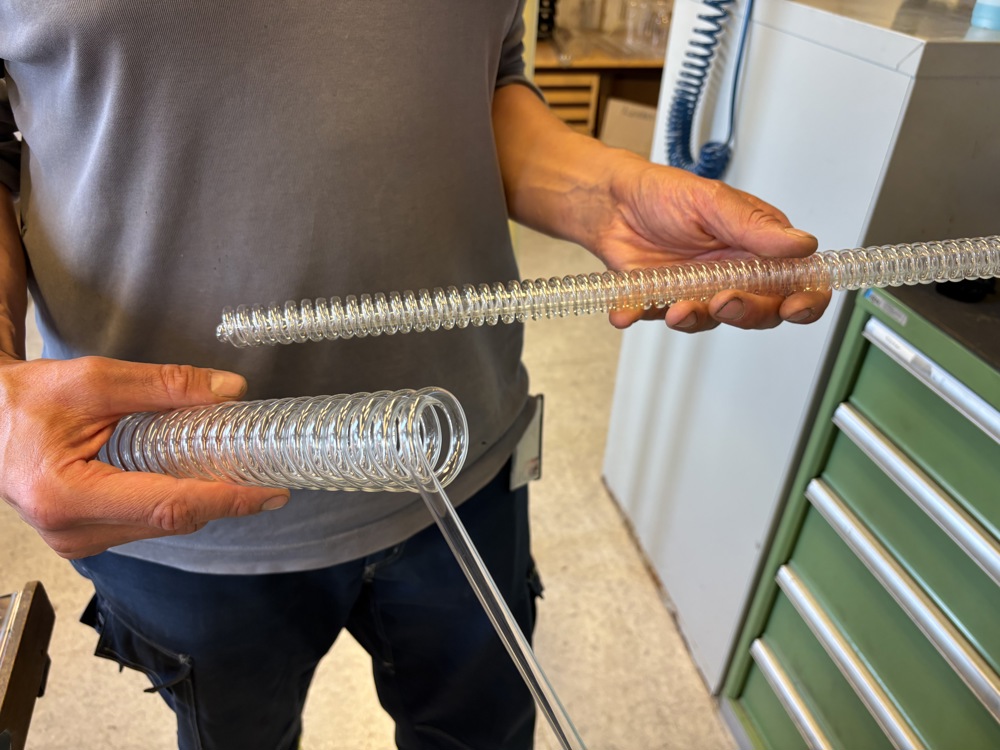

“It’s a real advantage for us that we can combine different materials to provide customers with optimal solutions for their projects,” says Kraft-Poggensee. “Glass has unique properties, and we have the expertise needed to integrate it with plastics and metals. Together with our customers, we develop solutions that work in practice.”

The workshop offers everything from test equipment to advanced prototypes and pilot plants.

“We’re flexible, and prototypes in glass are easy to modify. You simply heat them up and make the necessary adjustments – often in direct dialogue with the customer,” says Kraft-Poggensee.

Precision and craftsmanship

Glass is a demanding material to work with. It is fragile, prone to stress, and takes years of experience to master.

The glassblower works with pre-made tubes and components, which are customised and assembled according to the customer’s needs. The workshop holds a large stock of threaded tubing, taps, valves and other parts.

In addition, the glass workshop has machines and expertise for diamond-tool machining – not only for glass, but also for hard materials such as ceramics and hard metal.

A long history at Herøya

The glassblowing workshop has long traditions at Herøya. In earlier days, large pilot plants were built in glass to visualise processes before scaling up to full factories.

Today, Bilfinger’s plastics workshop operates the glass facility, serving customers in the industrial park and laboratory environments across the country.

Glass products continue to play an important role in laboratories and in research and development projects. Even though much is now digitally simulated, there remains a need for custom-made glass equipment.

“Glass is transparent, resistant to chemicals and withstands high temperatures,” says Kraft-Poggensee. “At the same time, it is easy to clean, which is crucial when testing chemical processes. We use different types of glass depending on the need, but primarily quartz glass, which can tolerate temperatures of up to 1,200 degrees.”

Text/photo: Tone Brekke tone.brekke@hipark.no